On the face of it, development of this product seemed to be direct

and simple. After all, there was never an issue with compressive

strengths, and weights were in line with the specifications. The

aggregate was easily hydrated and more importantly, could be

easily re-hydrated at the batch plant.

We heard of the problems in the field with Lightweight Concrete in

general, and we were determined to make our product as

userfriendly and predictable as possible, which led us to an

extensive testing program before we would release it.

Our early testing was an exercise in testing the limits of the

product, and the test were basically designed to fail so we could

test the limits. As we moved forward with the testing, we filtered the

information down to a manageable level, and began to fine tune

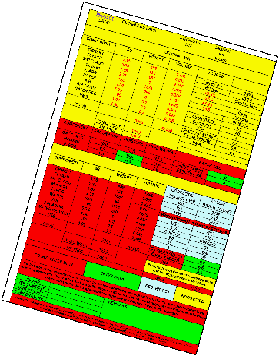

that information, out of which we developed a mix design calculator

with predictability and accuracy in mind.

and simple. After all, there was never an issue with compressive

strengths, and weights were in line with the specifications. The

aggregate was easily hydrated and more importantly, could be

easily re-hydrated at the batch plant.

We heard of the problems in the field with Lightweight Concrete in

general, and we were determined to make our product as

userfriendly and predictable as possible, which led us to an

extensive testing program before we would release it.

Our early testing was an exercise in testing the limits of the

product, and the test were basically designed to fail so we could

test the limits. As we moved forward with the testing, we filtered the

information down to a manageable level, and began to fine tune

that information, out of which we developed a mix design calculator

with predictability and accuracy in mind.

:: DEVELOPMENT HISTORY OF SRP ::

Most importantly all this testing revealed the optimum handling of

the material as well as documentation through testing on factors

such as moisture equilibrium and how that relationship affects

pumping in the field.

Finally, we tested material that was further processed in a trommel

to round the edges to see if this made the aggregate even more

pump friendly. Our tests proved that this process did further

improve the pumping through all the range of mixes. We then

worked with Doppstadt to application. This final process has been

incorporated into the product.

the material as well as documentation through testing on factors

such as moisture equilibrium and how that relationship affects

pumping in the field.

Finally, we tested material that was further processed in a trommel

to round the edges to see if this made the aggregate even more

pump friendly. Our tests proved that this process did further

improve the pumping through all the range of mixes. We then

worked with Doppstadt to application. This final process has been

incorporated into the product.

| Mix Design/Batch Control Calculator |

| designed Trommel. |

| Video Coming Soon! |